what is composite shell veneer or thick shell veneer?

Need a shell surface with more substance than standard veneer? Thin veneers might lack the rigidity or thickness needed for specific high-end applications, limiting your design or manufacturing options.

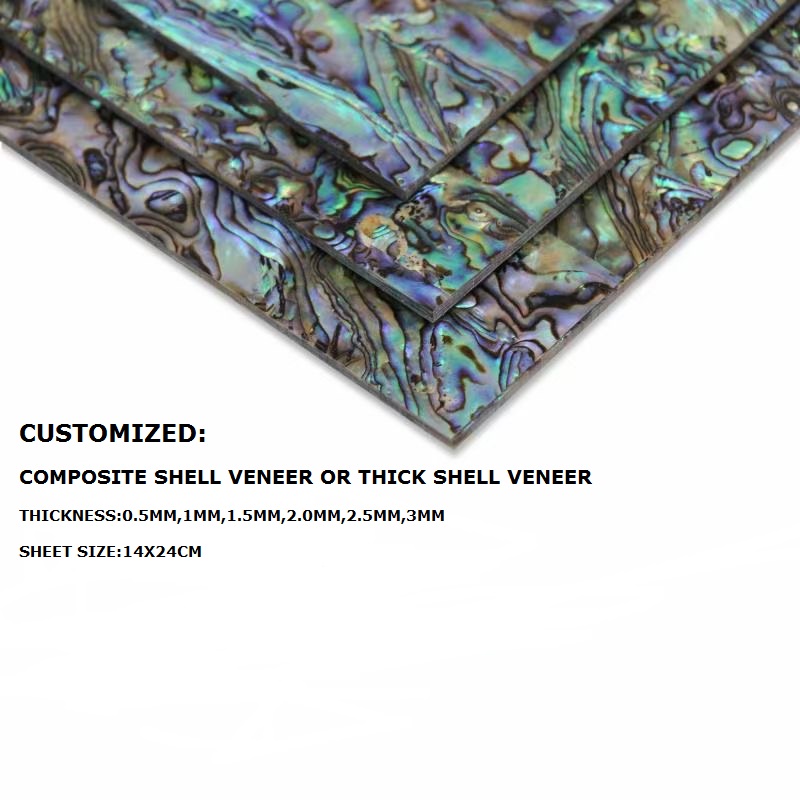

Composite or thick shell veneer is a multi-layered sheet made by bonding several layers of thin natural shell veneer together, resulting in a significantly thicker (0.5mm-4mm) and more rigid material.

Composite shell laminate or thick shell laminate

This specialized material offers a solution when standard shell veneer’s delicate thinness isn’t suitable. While sharing the beauty of natural shell, its unique construction gives it distinct properties and applications. Let’s explore how it compares to its common counterpart.

what’s the difference between common shell veneer and composite shell veneer?

Confused about which shell veneer suits your project? Choosing the wrong type could lead to application failure or unnecessary expense. Understanding the core differences is key.

The main differences lie in thickness (Composite: 0.5-4mm vs. Common: 0.15-0.3mm), construction (Composite: multi-layered/pressed vs. Common: single thin layer), and primary usage (Composite: instruments/dots vs. Common: broader surfaces).

THICK ABALONE SHELL DOTS

While both originate from beautiful natural shells, common shell veneer and composite/thick shell veneer serve different purposes due to their fundamental structural variations:

Thickness and Construction

This is the most significant difference.

- Common Veneer: Extremely thin, typically ranging from 0.15mm to 0.3mm. It consists of a single delicate layer of shell material.

- Composite/Thick Veneer: Substantially thicker, ranging from 0.5mm up to 4mm or more based on requirements. It’s constructed by laminating multiple sheets of thin shell veneer (often high-grade 2A or 3A) together using specialized adhesives and pressing techniques.

Material Options and Flexibility

Composite veneer offers flexibility in its build:

- Core Layers: To manage costs for thicker sheets, less expensive veneers (like freshwater shell) can sometimes be used for the internal layers, while premium shell remains on the visible surfaces.

- Base Material: For specific thickness requirements or properties, composite veneer can even be pressed onto a substrate like an acrylic sheet.

Usage Profile

Their applications differ significantly due to thickness and rigidity:

- Common Veneer: Highly versatile due to its thinness and flexibility. Used widely on walls, furniture surfaces, musical instruments (as thin overlays), jewelry, and decorative objects.

- Composite/Thick Veneer: Its thickness and rigidity make it ideal for applications needing more substance. Primarily used in crafting musical instruments.

| Feature | Common Shell Veneer | Composite / Thick Shell Veneer |

|---|---|---|

| Thickness | 0.15mm – 0.3mm | 0.5mm – 4mm+ |

| Construction | Single thin layer | Multiple thin layers laminated & pressed |

| Core Options | N/A | Can use lower-cost veneer or acrylic base |

| Rigidity | Flexible | More Rigid |

| Primary Use | Walls, furniture, surfaces | Musical instrument inlays, shell dots |

how is composite shell veneer or thick shell veneer made?

Curious how thin shell layers become a thick, solid sheet? The transformation seems complex, but it relies on precise lamination technology tailored for natural shell materials.

Composite shell veneer is made by carefully selecting thin shell veneer layers, applying adhesive, stacking them, and then pressing them under controlled heat and pressure until securely bonded into a single thick sheet.

[image placeholder]

Creating thick shell veneer is a multi-step process demanding precision to maintain the shell’s beauty while achieving desired thickness and stability:

- Veneer Selection: High-quality thin shell veneers (e.g., Grade 2A or 3A common veneers) are chosen for the outer layers to ensure premium appearance. If cost optimization is needed, suitable lower-grade or freshwater veneers might be selected for inner, unseen layers.

- Adhesive Application: A specialized adhesive, suitable for bonding shell material without discoloration or degradation, is uniformly applied between each layer of veneer.

- Layering (Stacking): The adhesive-coated veneers are carefully stacked in the desired orientation and sequence. If an acrylic or other base is required, it’s incorporated at this stage.

- Pressing: The stack is placed into a press. Controlled heat and significant pressure are applied for a specific duration. This activates the adhesive and forces the layers into a tight, permanent bond, eliminating air gaps.

- Curing & Finishing: After pressing, the newly formed thick sheet is allowed to cure completely. It may then undergo cutting, sanding, or polishing to achieve the precise final thickness, dimensions, and desired surface finish.

what is the usage of composite shell veneer or thick shell veneer?

Wondering where exactly this thicker shell veneer is applied? Its specific properties make it less versatile than thin veneer, focusing its use on demanding niche applications.

Composite/thick shell veneer is primarily used in crafting high-end musical instruments for applications like thicker fretboard inlays, headstock decorations, or for pressing/cutting into dimensional shell dots.

[image placeholder]

Unlike the broad applicability of common thin shell veneer, the usage of composite or thick shell veneer is more specialized, leveraging its increased thickness and rigidity:

Musical Instruments: The Primary Application

This is where thick shell veneer truly shines.

- Inlays: Guitar makers, luthiers crafting ukuleles, banjos, and other stringed instruments use thick veneer for decorative inlays on fretboards, headstocks, bridges, and bodies. The thickness provides necessary substance for routing pockets and ensures the inlay sits flush and securely without being too fragile.

- Shell Dots: Small position marker dots on fretboards are often made from thick shell veneer. The material is thick enough to be pressed or cut into small, durable cylindrical or shaped dots.

Other Potential Niche Uses

While less common, its properties could lend themselves to:

- Luxury Box Making: Providing durable decorative elements with tangible depth.

- Specialized Architectural Details: Where a thicker, self-supporting shell element might be needed.

- High-End Jewelry/Accessories: Creating pieces with more dimensionality than thin veneer allows.

Its use is generally dictated by applications where the 0.15-0.3mm thickness of standard veneer is insufficient structurally or aesthetically.

Conclusion

Composite shell veneer is a specialized, multi-layered, thicker (0.5-4mm) product. Distinct from common veneer, it’s made by pressing thin layers and primarily serves demanding musical instrument applications like inlays and dots.