The Usage of Abalone Shell Veneer: How Can It Transform Your Design Projects?

Shell veneer offers a luxurious natural material that brings depth and iridescence to any project. Many designers struggle to find truly unique decorative elements that elevate their creations above the ordinary.

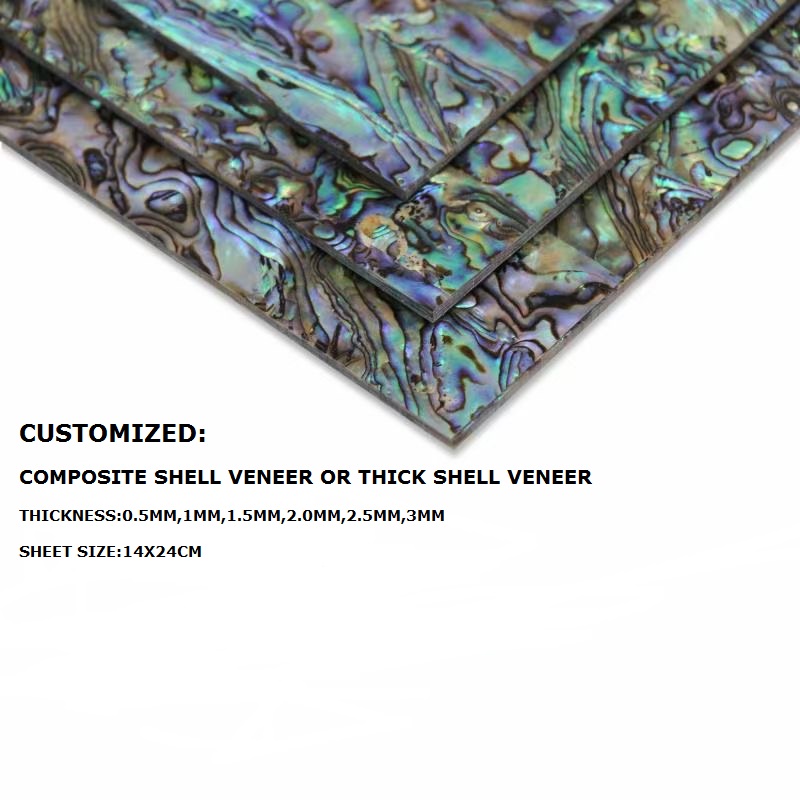

Shell veneer is a thin slice of natural seashell material (typically 0.2-0.4mm thick) that's been processed into flexible sheets measuring approximately 140x240mm. These natural laminates showcase the shell's iridescent layers and can be cut, applied to surfaces, or used as inlay material for decorative purposes.

The versatility of shell veneer is truly remarkable. From musical instruments to fine furniture, these natural sheets bring organic elegance to countless applications. Let's explore the different types available and how they can transform your next project.

What Is Shell Veneer and How Does It Enhance Design Projects?

Designers face constant pressure to create distinctive pieces that stand out in a crowded marketplace. Shell veneer provides the perfect solution with its one-of-a-kind patterns and colors.

Shell veneer consists of thin, flexible sheets made from natural seashells like abalone, mother of pearl, and paua. These sheets capture the natural iridescence and unique patterns of each shell, creating decorative surfaces that can be applied to various materials including wood, metal, and synthetic bases.

Understanding Shell Veneer Properties

When working with shell veneer, it's important to understand its unique characteristics:

| Property | Description | Design Implication |

|---|---|---|

| Thickness | Typically 0.2-0.4mm | Thin enough for inlay work, requires careful handling |

| Flexibility | Moderately flexible | Can be applied to curved surfaces with proper adhesive |

| Durability | Hard but brittle | Needs protective finishes for high-wear applications |

| Light Interaction | Iridescent | Creates dynamic visual effects as lighting conditions change |

Shell veneer's natural brilliance comes from the same microscopic structure that gives pearls their luster. This makes each piece not just decorative but a genuine natural wonder that can't be perfectly replicated by synthetic materials. The thin layers of calcium carbonate reflect light in ways that change depending on viewing angle, creating depth and dimension unmatched by painted or printed alternatives.

How Many Kinds of Shell Veneer Are Available for Your Projects?

Crafters often settle for standard materials, missing opportunities to make their work truly distinctive. The wide variety of shell veneers offers a solution to this creative challenge.

There are several major types of shell veneer including abalone (with blue-green iridescence), white mother of pearl (silvery white), gold/yellow mother of pearl (warm golden tones), black mother of pearl (dark with colorful highlights), paua (vibrant blues and greens), and freshwater shell (subtle pinks and creams).

Comparing Shell Veneer Varieties

Different shell varieties offer unique aesthetic qualities for specific applications:

| Shell Type | Color Range | Best Applications | Visual Characteristics |

|---|---|---|---|

| Abalone | Blue-green with rainbow highlights | Guitar inlays, luxury furnishings | Bold, colorful, high contrast |

| White MOP | Silvery white with pastel highlights | Jewelry, fine inlay work | Subtle, elegant, traditional |

| Gold/Yellow MOP | Warm golden tones | Classic instruments, warm-toned projects | Rich, traditional, golden glow |

| Black MOP | Dark with colorful flashes | Modern design, dramatic accents | Contemporary, striking, high contrast |

| Paua | Vibrant blues and greens | Statement pieces, artistic applications | Intense color, dramatic patterns |

| Freshwater | Subtle pinks and creams | Delicate work, feminine designs | Soft, understated, natural |

The choice of shell veneer significantly impacts the final appearance of your project. Abalone's bold patterns make a statement in visible decorative elements, while the more subtle mother of pearl varieties often complement traditional designs. Understanding these differences allows designers to select precisely the right material for creating the desired aesthetic and emotional response.

How to Make Shell Veneer for Premium Applications?

Many craftspeople struggle with inconsistent materials that compromise their finished products. Quality shell veneer production involves precise techniques that ensure reliable results.

Shell veneer is created by carefully cutting, grinding and polishing natural shells to a uniform thickness of 0.2-0.4mm. The shells are first cleaned and flattened, then precisely cut using specialized equipment. Finally, the pieces are polished to reveal their natural iridescence while maintaining structural integrity.

Abalone shell veneer making way

The Shell Veneer Manufacturing Process

The creation of high-quality shell veneer involves several precise steps:

Raw Material Selection

- Only certain shells with sufficient thickness and coloration are suitable

- Sustainable sourcing practices ensure environmental responsibility

Preparation and Cleaning

- Shells undergo thorough cleaning to remove organic residue

- Heat and chemical treatments may be used to enhance workability

Cutting and Processing

- Precision cutting equipment slices shells to uniform thickness

- Each piece is carefully inspected for quality and consistency

Finishing

- Final polishing brings out the natural luster

- Edges are finished for clean application

- Backing may be applied for additional stability

The quality of shell veneer directly correlates with the care taken during each step of production. Modern manufacturing techniques allow for consistent thickness and finish while preserving the natural beauty of each unique shell. Solar Shell's commitment to quality control throughout this process ensures that each sheet meets exacting standards for both aesthetic appeal and practical application.

Conclusion

Shell veneer, particularly abalone, offers extraordinary natural beauty and versatility for countless decorative applications. From guitars to fine furniture, these thin, iridescent sheets bring unique character to any project.